Land & Marine

Loading Arms Kenya.

Zero-Demurrage Terminal Operations

Belgian Engineering. Depot Efficiency.

Stop using slow, unsafe hoses. Upgrade to API-compliant Top & Bottom Loading Arms for rapid, vapor-tight tanker filling.

Loading Method Selection

Ref: PV-LOAD-SELECT-2026| System Type | Safety Standard |

Key Advantage | Throughput Speed | Primary Application |

|---|---|---|---|---|

|

Bottom Loading (API)

|

API RP 1004 Ground Level Operation |

Vapor Recovery (Safe) No Static Charge Risk |

2,500 LPM+ | Fuel Depots / Petrol |

|

Top Loading

|

Safe Working at Height Requires Folding Stairs |

Versatile Reach Fits any tanker hatch |

1,200 LPM | Chemicals / Bitumen / Edible Oil |

Marine Loading Arms

The safest link between ship and shore. Designed for the harsh corrosive environment of Mombasa's terminals. Integrated with high-capacity pumps for rapid vessel turnaround.

- Size

- 4" - 20" (DN100 - DN500)

- Operation

- Manual / Hydraulic Remote Control

- Standard

- OCIMF Design Guidelines

Ideal Applications:

Jetty Loading, Ship-to-Shore Transfer, Bunkering

Did you know?

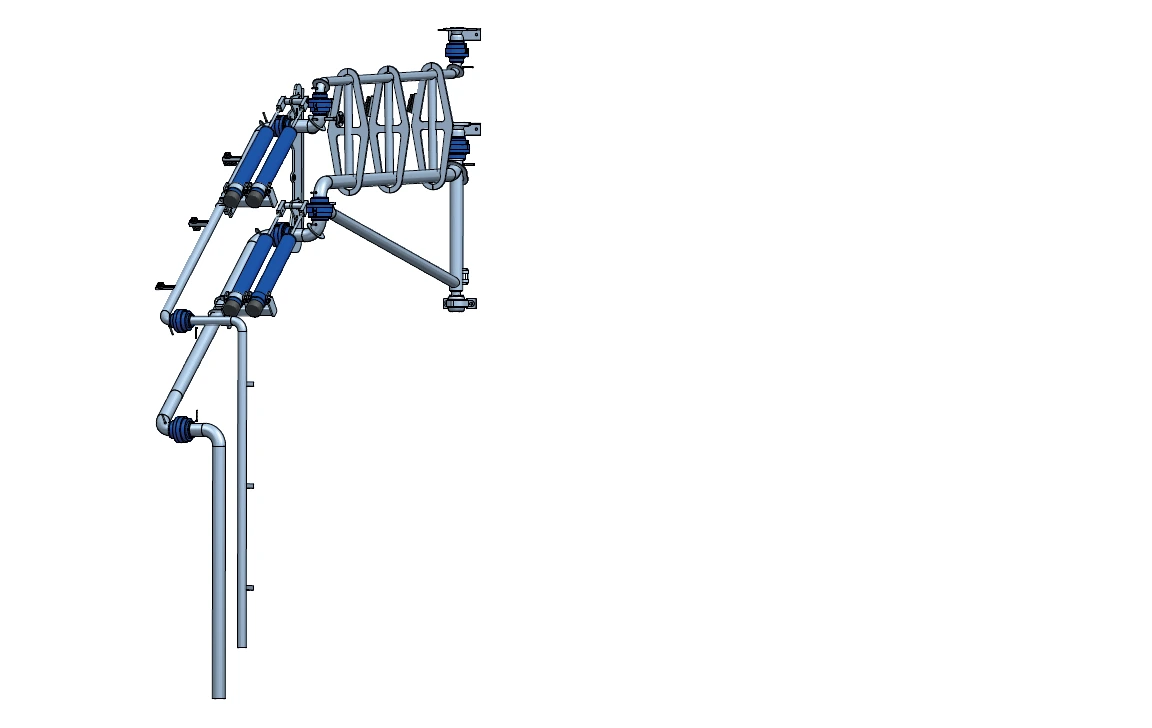

Land Loading Arms

Counter-weighted articulation for effortless operation. Available in Bottom Loading (Fuel) and Top Loading (Chemical) configurations for efficient depot automation.

- Size

- 2" - 6" (DN50 - DN150)

- Coupler

- API 1004 / Dry Break / Flanged

- Safety

-

Break-Away: Protects against drive-offs

Overfill: Optical Sensors

Ideal Applications:

Petroleum Depots, LPG Terminals, Chemical Plants

Did you know?

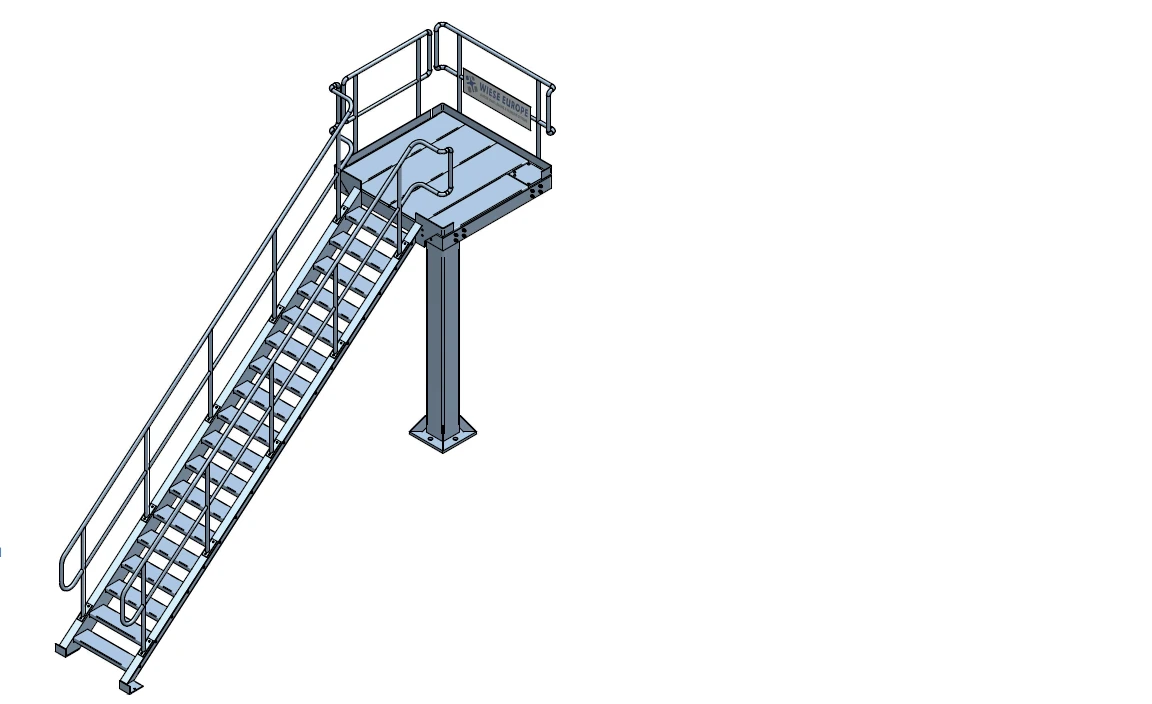

Folding Stairs & Safety Cages

Secure access for top-loading operations. Self-leveling steps and full perimeter cages ensuring OSHA and local safety compliance.

- Steps

- 3 / 4 / 5 Steps (Adjustable Reach)

- Width

- 800mm - 2000mm (Double Width)

- Certification

- TÜV / CE / OSHA

Ideal Applications:

Tanker Truck Gantries, Railcar Access Platforms

Did you know?

Projected Annual Revenue Recovery: $152,000

Quantify your operational inefficiency. Calculate the precise financial impact of manual hose delays versus automated loading arm throughput.

Maximize terminal profitability. Transition to automated loading.

Claim Revenue Now

Operational Efficiency

Frequently Asked Questions

Operational Speed

Transitioning: Top vs. Bottom Loading?

Transitioning: Top vs. Bottom Loading?

- ▪Risk: Top loading creates fall hazards and restricts flow rates.

- ▪Solution: Bottom loading (API 1004) enables safe ground-level operation.

- ▪Result: 2,500+ LPM throughput and 100% Vapor Recovery compliance.

Coastal Resilience

Marine Arms & Tidal Variance (Mombasa)

Marine Arms & Tidal Variance (Mombasa)

- ▪Risk: Flexible hoses rupture under high tidal tension at Kipevu.

- ▪Solution: Self-supporting, articulated pantograph arms.

- ▪Result: Safely handles 10m+ tidal lift without stressing ship manifolds.

Revenue Recovery

ROI Impact: Vapor Recovery Units (VRU)

ROI Impact: Vapor Recovery Units (VRU)

- ▪Impact: Captures 99% of displaced fumes during loading.

- ▪Speed: Allows simultaneous loading without pressure throttling.

- ▪Result: Cuts tanker turnaround by 30-50%, slashing demurrage costs.

Audit Compliance

Governing Safety Standards

Governing Safety Standards

- ▪Land: API RP 1004 & ATEX Zone 1 (Explosion Proof).

- ▪Marine: OCIMF Design Guidelines.

- ▪Tech: Emergency Release Couplers (ERC) for zero-spill disconnects.

Site Engineering

Engineering Customization & Retrofitting

Engineering Customization & Retrofitting

- ▪Process: We conduct comprehensive site surveys to model gantry geometry.

- ▪Specs: Reach up to 6m, telescopic drop-pipes, heated tracing for viscous fluids.

- ▪Result: Seamless integration into existing piping infrastructure.